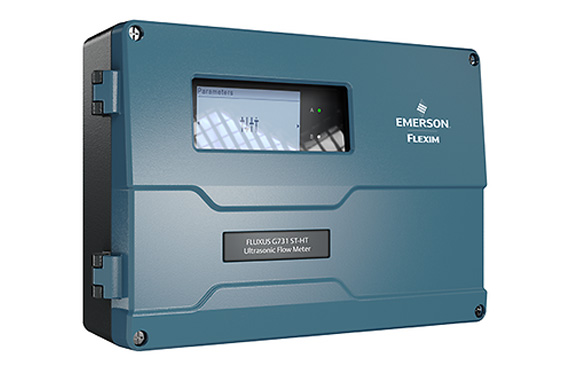

The Flexim FLUXUS G731 ST-HT delivers reliable, non-intrusive flow measurement of superheated steam at extreme temperatures—up to 630 °C (1166 °F)—without penetrating the pipe. Utilizing a correlation-based ultrasonic method, this advanced system achieves high measurement accuracy with excellent dynamic response, regardless of flow direction.

Designed for bi-directional flow measurement, the G731 ST-HT supports a wide turndown ratio of up to 10:1, ensuring precision across varying flow rates. Since it operates entirely from the pipe’s exterior and contains no moving components, it eliminates wear-related maintenance and offers long-term operational savings.

Installation is quick and non-disruptive, requiring no shutdowns or process interruptions. This makes the FLUXUS G731 ST-HT an ideal, cost-effective upgrade for existing steam systems where performance, reliability, and minimal maintenance are critical.