Author: Mike Greer, P.Eng.

Introduction

In today's data-driven environment, digital transformation source data often comes from historical protection instrumentation. As a result, the data used in higher level networks often lack resolution and information. Understanding the full capabilities of protection systems and instrumentation can unleash valuable information to further define models and system behavior.

When creating any model or evaluation of a system’s performance, there can be many parameters that are overlooked due to either ignorance or inexperience. By understanding the full capabilities of the data sources, consideration into the destinations of the datasets can be more efficiently defined; like stereophonic listening, the data source often determines the satisfaction of the listeners enjoyment.

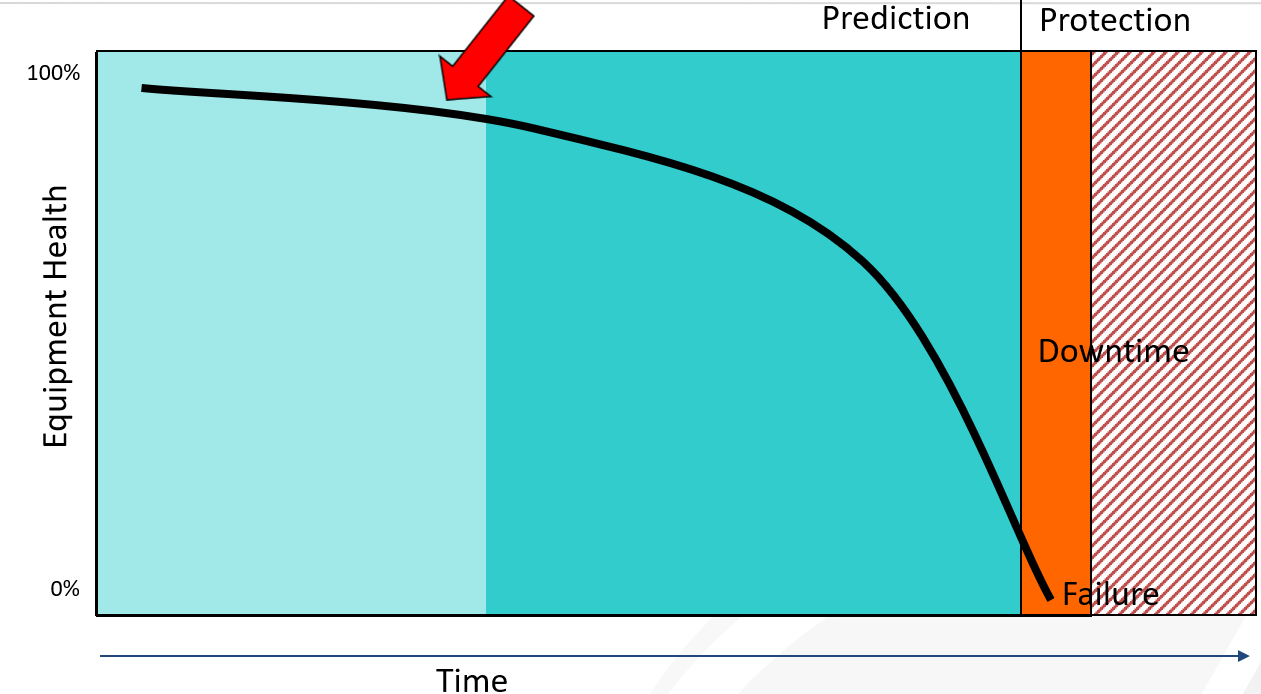

Protection systems are designed to identify failure modes before they can cause catastrophic failure. This begins with the economical evaluation of a device that can sense a change related to the failure mode wishing to be avoided. Vibration sensors are often used to determine a change in energy of an asset such as motors, turbines, compressors, or fans etc.

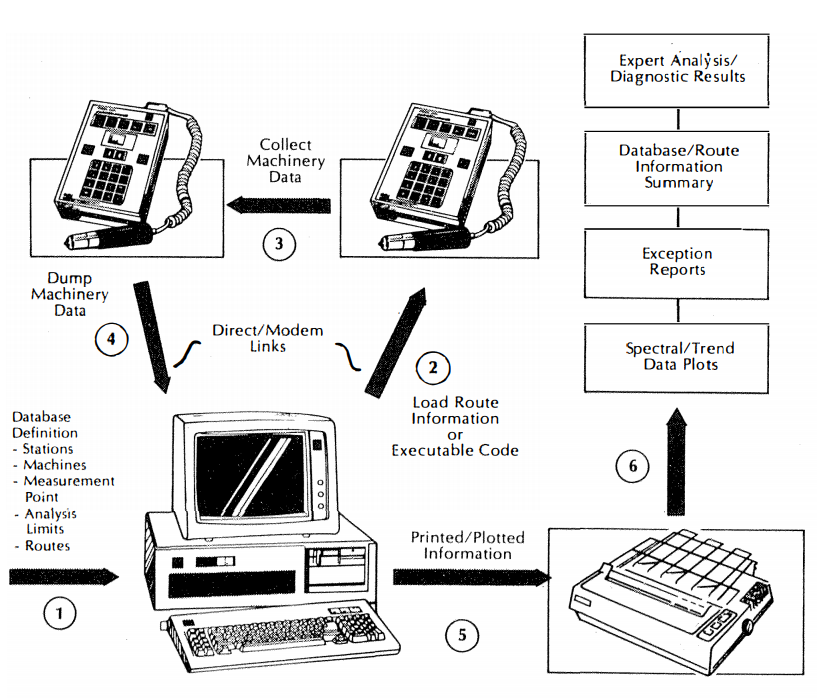

In the 1960s, assets that would impact production used the measurement of a shaft’s movement or displacement in relation to the bearing housing as the primary method of determining if something was wrong. The conversion of mechanical energy to an electrical signal allowed the determination of thresholds and when exceeded, shutdown procedures would initiate. While these systems were effective, they were cost-prohibitive and only deployed on large critical assets that had a huge impact on production. The resulting output of these systems was often a scalar value. These scalar values were often utilized to determine the overall health of a machine post and pre-shutdown but lacked accuracy in determining the root cause of any functional failure.

Asset owners now had two sources of data to determine the health and reliability of their assets. One data source was relatively simple, utilizing scalar values, and the other was often complex, with both scalar and complex data arrays but at a longer interval. Often, the individual data depositories were located on different infrastructure networks, some in the process control network, some in the plant historians, and some residing in software application databases.

At the turn of the century in the mid-2000s, organizations realized that they could harvest the information from these two discrete data sources. The first step was often dynamic extraction from protection systems into plant process historians. This was easier as the values were scalar and the transfer of this information was already being done from the data source to the control systems in most of the facilities.

The complex data often languished in the bowels of maintenance programs and were not used for any cause or process control purposes. With the advent of more complex networking inside organizations, there was a realization that this alternative data source existed.

Integration of protection and prediction data sources was common practice in the early 2010s, along with the acceptance of wireless vibration data sources. The realization that complex data was now available to historians, and subsequent machine learning systems, opened the conversation as to which data source was the most valid for the various models being considered.

The realization that decades of data are now available to harvest and provide improved modeling now created another challenge.

How did this data compare to the previous scalar data when defining or creating a model that could be applied to complex machinery functional failures and process and production efficiencies? The instrumentation or sensors had not changed in over 30 years, although the processing and information derived from those sensors were now deemed information rich.

As we migrate from application specific evaluation to a more holistic approach to organizational impact, the jockeying for position of all the competitive parameters that build up a model need to be evaluated and often result in historical performance evaluation.

Spartan Controls can provide the services to evaluate the current data available in your data repositories, as well as evaluate the equipment currently utilized for asset monitoring, and provide recommendations for where newer technologies can be implemented to gather richer data.

Our next post will explore the challenges and solutions that are encountered as data/information is more commonly streaming versus fetched.

Learn more about our Reliability Solutions

https://www.spartancontrols.com/solutions/reliability-solutions/