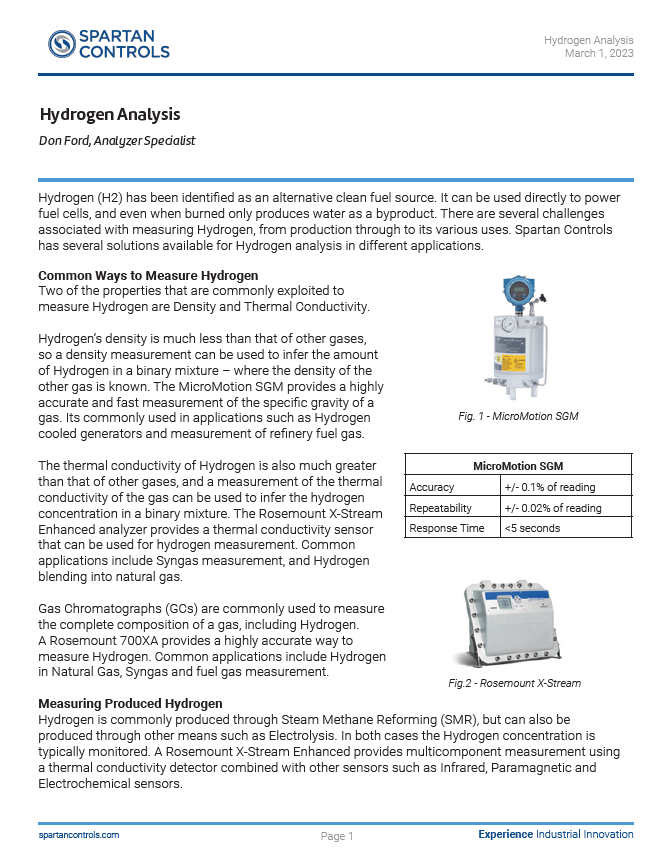

Hydrogen Production

Hydrogen is the cleanest burning and most efficient fuel . It exists naturally on Earth but not in large quantities in its elemental form and is produced industrially in several ways. Common methods of hydrogen production include Steam-Methane Reforming (SMR), Autothermal Reforming (ATR), as well as Gasification, Pyrolysis or Electrolysis of water. In all of these processes, automation plays an important role in ensuring safe, reliable and efficient operation while minimizing costs.