Ensure Compliance with EPA Regulations

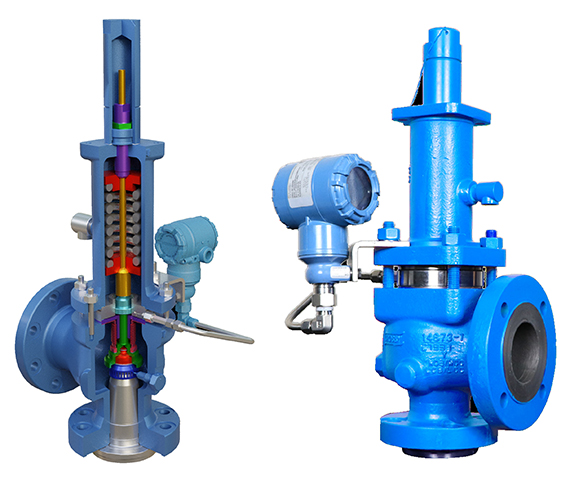

Crosby Bellows Leak Detection

Introducing Crosby Bellows Leak Detection:

- Remote detection of bellows ruptures in PRVs

- Accurate calculation of volumetric emissions in real-time

- Addresses the challenges of detecting bellows failures

- Reduces the risk of overpressure events and fugitive emissions

- Overcomes difficulties in accessing PRV installations and hazardous locations

- Remote detection of bellows ruptures in PRVs

- Accurate calculation of volumetric emissions in real-time

- Addresses the challenges of detecting bellows failures

- Reduces the risk of overpressure events and fugitive emissions

- Overcomes difficulties in accessing PRV installations and hazardous locations