Machinery Health Services

Trust our full suite of proven reliability solutions

Connect with a Specialist

Book an appointment with a specialist to discuss your Machinery Asset Health .

We provide a full suite of solutions for all of your rotating equipment reliability needs.

Download Brochure

Spartan’s machinery asset specialists provide lifecycle expertise, from reliability program design to day-to-day machinery condition health solutions.

Selection of vibration, pressure, temp, UT, ultrasonic monitoring points and orientation on rotating equipment in scope.

Support customer to gather field engineering data requirements and conduct constructability reviews

Wi-HART sensor locations confirmation.

Spartan's consultants assist clients to develop their condition monitoring program based on understanding failure modes and how to detect and mitigate them. They can determine the appropriate technology and help integrate that into a comprehensive condition monitoring package with reporting and alerts. In addition our consultants can help integrate this program into the maintenance work flow process to ensure repairs are planned, scheduled and executed in a cost-effective manner.

Spartan has developed program assessment tools for Vibration, Instrument and Valve monitoring and Maintenance & Reliability programs to identify gaps to best practice and to recommend a road map for improvement.

We offer expertise in the SAE-JA1011 methodology, and can provide you with formal consultations on Failure Mode and Effects Analysis (FMEA) and Reliability Centered Maintenance (RCM) processes.

Lubrication analysis examines machine health by assessing lubricants. Our experts evaluate the quality, composition, and performance of oils and greases used in rotating equipment. By analyzing samples, they detect signs of wear, contamination, or degradation. Their expertise optimizes machinery performance, reduces downtime, and extends equipment lifespan. Whether assessing viscosity, detecting particles, or monitoring wear metals, our Spartan specialists play a vital role in maintaining reliable and efficient machinery across industries.

Reports generated of recommendations for existing monitored plant assets.

Reciprocating compressors have centrifugal and reciprocating movements that most technicians are not trained or experienced with in a single asset design. Signet Monitoring & Analysis has decades of experience with these assets and often provide design criteria to OEMs for improvement of them. Complementing that experience, our technicians can use portable stand alone and online technologies to capture true performance characteristics, such as engine load during testing, and recommend proactive maintenance strategies.

Learn More

Signet Monitoring & Analysis provides unbiased, third-party emissions strategies to quantify your emissions and plan your emissions program. This program is designed to help companies achieve regulatory compliance, including adherence to the new federal MSAPR (Multi-Sector Air Pollutants Regulations). Additionally, Signet aims to make emissions programs cost-effective and practical. Their emissions testing team, collaborates with your current tuning companies to ensure engines meet targeted emissions levels.

Learn More

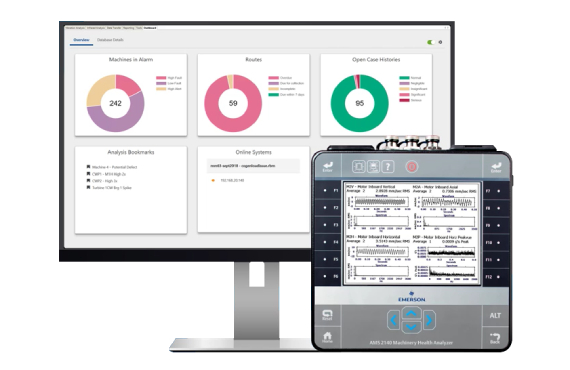

Vibration Asset Monitoring Solutions

The industry standard tool that elevates vibration data and analysis measurements.

Online Machinery Asset Monitoring & Process Analytics at the Industrial Edge. Monitor or shut down your most critical plant assets in real-time.

Proven Results

One of our senior machinery asset specialists performed an analysis on the critical high-speed compressor and recommended an immediate bearing design change. Temporary measures were implemented, mitigating vibration while increasing production until a shutdown was planned and permanent bearing changes could be made. Spartan’s solution allowed the plant to continue to operate until shutdown, and then after the design change, production was increased by 25%.

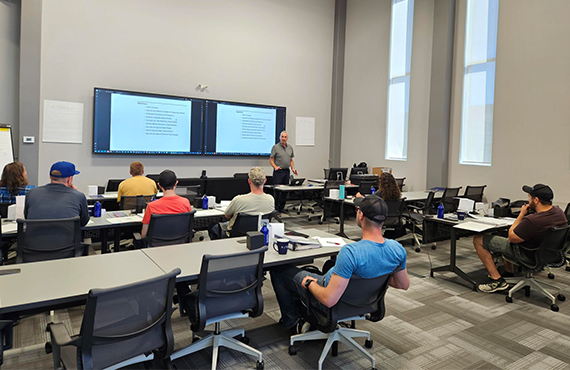

Education

Spartan offers factory-authorized training for approximately 1,000 students annually at our Edmonton Automation Centre. Additionally, we have the capability to conduct on-site training at our Certified Training Centres spread throughout Western Canada. Our Vibration Analysis Compliant courses are designed to impart essential knowledge, covering topics such as the use of portable machinery analyzers, the management of dumping and loading routes, the discernment between reliable and unreliable data, and the evaluation of vibration measurements against established alert criteria.