Author: Devin Marshman, Spartan Controls and David Harrach, Emerson

Ore processing operations connected with mining sites are a critical but costly step in the larger effort to produce refined metals. Regardless of the final purification process, ore must be prepared to meet refiner composition specifications, create optimal particle size, support preliminary separation, and impart other characteristics necessary to ensure efficient final separation, whether by chemical means or traditional smelting. Steps can involve grinding, screening, thickening, flotation, and others to achieve the desired intermediate product.

These steps depend on automated process control to maximize recovery of on-spec product in a cost-effective manner. Grinding operations are generally the most energy intensive steps of a processing plant, often consuming up to 10 kilowatt hours per ton of ore processed. Selecting the most effective control strategies for this and other processing equipment is the subject of much discussion at many mining companies given the enormous stakes involved.

The ability to shave even a few percentage points off total energy consumption per ton can result in huge increases to a facility’s bottom line, along with substantial improvements to efficiency and sustainability.

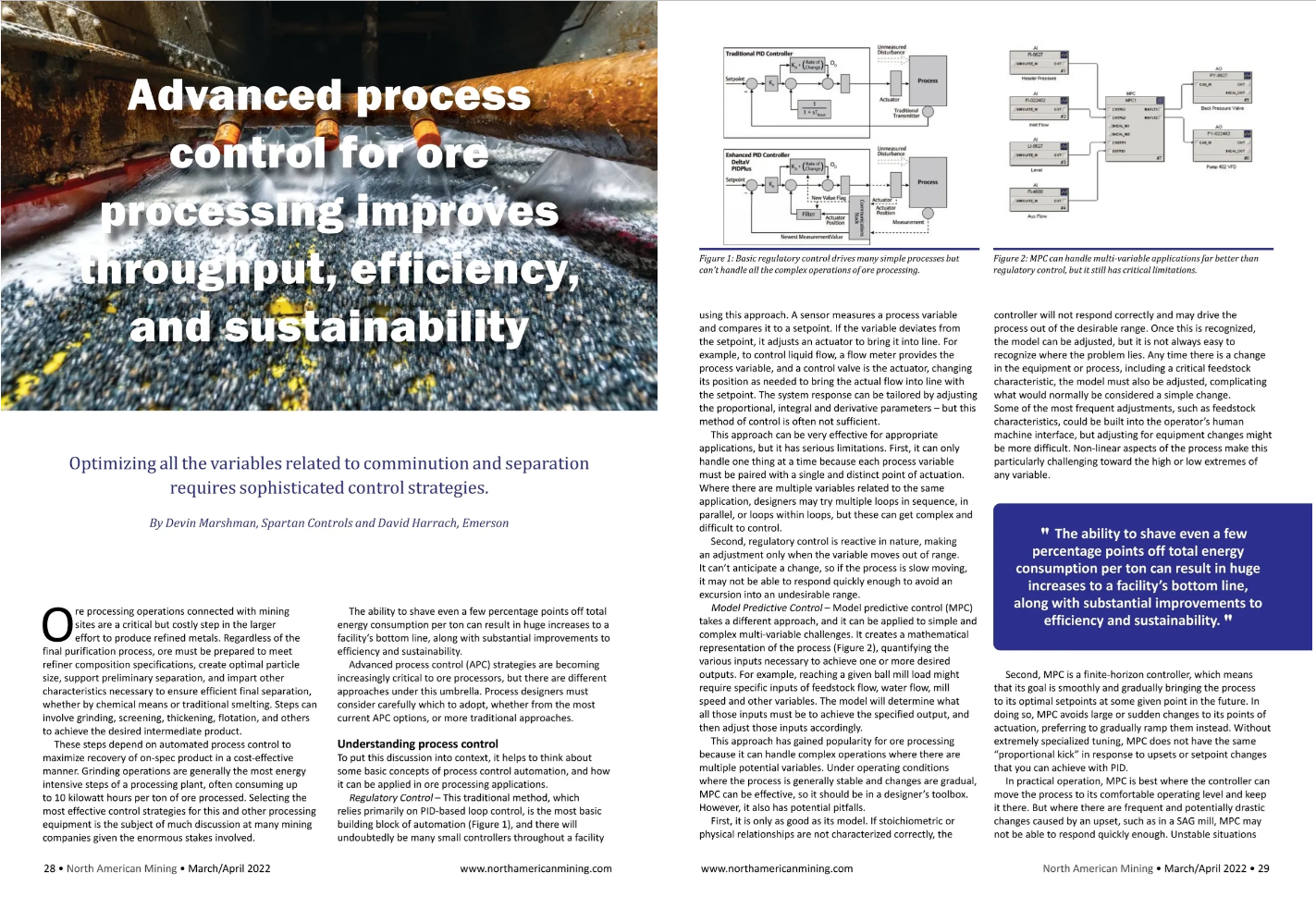

Advanced process control (APC) strategies are becoming increasingly critical to ore processors, but there are different approaches under this umbrella. Process designers must consider carefully which to adopt, whether from the most current APC options, or more traditional approaches.

Full Article Below...