Author: Gabe Fantino

Know When it's Time

Once graphics are commissioned, we have found that getting them improved is typically a hard sell. The question usually becomes: does the Human-Machine Interface (HMI) still work? If the answer is “yes” or “sort of,” then why change?

It’s like a broken gate at the front of someone’s house. You struggle to navigate into the backyard, it takes way more effort than it should, looks shabby, but it somewhat works so the motivation isn’t there to fix it, unlike, say, a sewer back-up - that gets attention pronto!

Current State

The fact is your graphics are probably pretty good. You’ve spent years and a lot of money to match them to the way your operators work. But they are dated. Sprawling. Don’t conform to modern Human Centered Design (HCD) concepts. And worst of all, they are hard to access by various stakeholders within the organization. Sure, your corporate historian has tons of process data, but there are some gaps such as alarms and alarm setpoints, tuning constants, interlocks, conditional alarming, sequence status, well testing and lab data. The list goes on.

Ensuring the HMI isn’t a barrier

Don’t let outdated interfaces be a barrier for your organization’s digital, production and business objectives. At some point, most automation managers will be asked what they have done to prepare the department for the challenges of a changing digital workforce, diffuse work locations, and data portability.

These days it’s about getting the right data to the right people, not bringing the people to the data. Current graphics may work, and may even have remote connectivity options, but is your data truly portable? Does the interface encourage learning? Is it friendly to new hires? Does it support smart decision-making?

"Put ROI in context: you’re not doing it primarily to make money, but you will make money after it is done, and more importantly, you as an automation manager won’t be a barrier for the organization to increase revenues down the road: you’ll be ready"

Where does management think the workforce five years hence will come from? You guessed it. Operator training and retention is a key challenge, and a modern operator interface is a big part of attracting individuals who have an innate affinity for the user experience.

Future State

We believe HMI design should be about form following function. If your interface looks, feels and conforms to standards like other modern interfaces, then training, onboarding, and performance benefits will likewise follow.

In the design world, this is called Jacob’s Law: users prefer an interface to behave like other modern interfaces. Spartan can help ensure this is the case, incorporating current concepts around situational awareness, abnormal situation monitoring, upset-recovery, and advanced procedure automation in any HMI modernization project.

HMI Project Justification

We all know projects get approved when a business case can be made. Basic, right? Here are some strategies to getting the green light to modernize the graphics, integrate interfaces, and aggregate data; in other words, to prepare for the digital transformation that is well underway.

Know the Differences Between Operations and Automation

As automation professionals, we live and breathe control signals, instrumentation, effective presentation of the wall of information coming from our controls systems, and of course how to best interact with those systems. Operators, well, they want to operate their plants safely, securely, and with tools that make their lives easier. Remember, operators typically spend 12 hours a day in front of their consoles. Their world looks a bit different; gazing into the eyes of the plant through a variety of interfaces of disparate design/vintage, ensuring production objectives are met, high-stress upsets are corrected, and maintenance is safely executed on many of the plants critical sub-systems. Therefore, it’s important to have a measure of empathy and involve operations early in any HMI upgrade. They will be your greatest supporter once they see how an improved interface will streamline operations for years to come.

"Involve operations early in any HMI upgrade. They will be your greatest supporter once they see how an improved interface will streamline operations for years to come. possible."

ROI calculations encourage buy-in. But ROI is not all about money. Be realistic, but you don’t have to account for every detail. ROI calculations are estimates, not financial projections. You won’t likely know the return until later. Before you go around showing a calculated ROI to your team, make sure they understand the context and rationale for the HMI upgrade. You’re not doing it primarily to make money, but you will make money after it is done, and more importantly, you as an automation manager won’t be a barrier for the organization to increase revenues down the road: you’ll be ready.

Besides moving closer to meeting auditable global interface standards such as ISA 101, there will be improved efficiency for lower maintenance and support costs. Operationally, it’s realistic to expect decreased downtime with better situational awareness; faster start-up by tuning the new interface for procedure automation and upset recovery. On the data management side, aim for:

- Enhancing plant and network security through secure remote access

- Improving access to data for smarter decision-making

- Optimizing data quality and proactively using technology to aggregate data before there is an internal demand for it

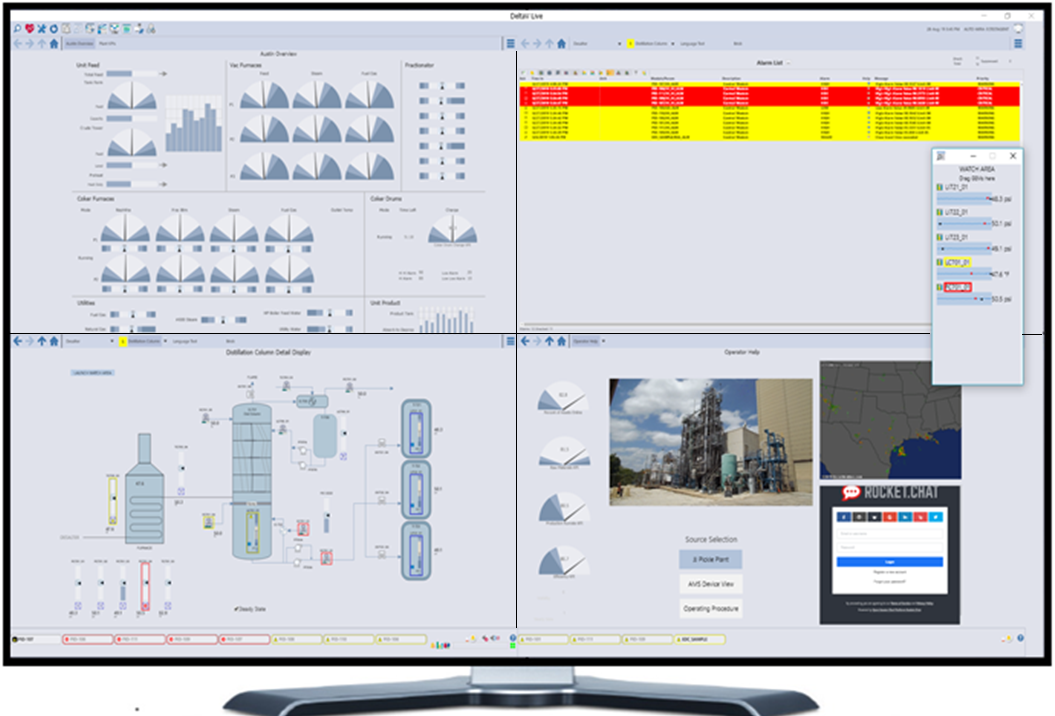

This is where Emerson’s new graphics engine and advanced operator interface comes in, as the

new face of a DeltaV system, or as a stand-alone HMI solution that can reduce Islands of Automation. DCS, PLCs, compressors, vendor skids, analyzers, electrical systems monitoring, vibration, Burner Management Systems all with their own HMI’s? Unfortunately, this is typically the reality.

Begin to reduce Islands of Automation, unify operator interfaces and build up data portability and integrity with the new DeltaV Live HTML5-based advanced operator interface joined to Emerson’s edge controllers, EtherNet data integration devices, or Data Lake products, all hardened for industrial applications and cyber-security.

DeltaV Live Delivers:

- Built-in color salience and other HCD features for ISA 101-compliance

- Integrated scalable, zoomable, HTML-based vector graphics, screen resolution & size-independent display sets

- Smart Navigation Bar: “no-programming” automatically generated navigation

- Alarm Rollups: displays alarms associated with linked graphics

- Sparklines show trends everywhere

- Declutter with Progressive Disclosure revealing details when necessary

- Switch HCD color themes on-line (day/night mode)

- One common graphics database natively supported by the vendor (no risky 3rd-party dependencies)

- State-Based Control for advanced users