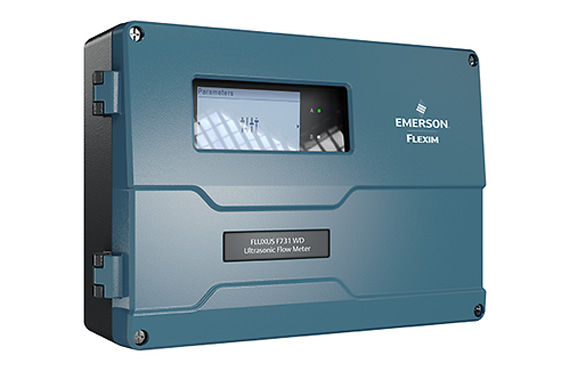

The FLUXUS F731 WD from Flexim offers a highly effective, non-invasive solution for flow monitoring in both potable water and wastewater systems. This ultrasonic flow meter allows for quick, economical clamp-on installation, eliminating the need for pipe modification in existing water infrastructure.

Engineered for precision and reliability, the F731 WD excels in measuring extremely low flow velocities—as low as 0.01 m/s (0.03 ft/s)—making it especially well-suited for leak detection and nighttime flow analysis. With permanently mounted transducers and robust IP68 protection, the system is ideal for use in harsh environments, including flooded areas and underground installations.

Building upon the capabilities of the F532 WD, the F731 WD supports pipe diameters exceeding 2000 mm (79 in) and features dual-channel measurement along with a wide range of communication interfaces, offering enhanced flexibility for complex monitoring needs.