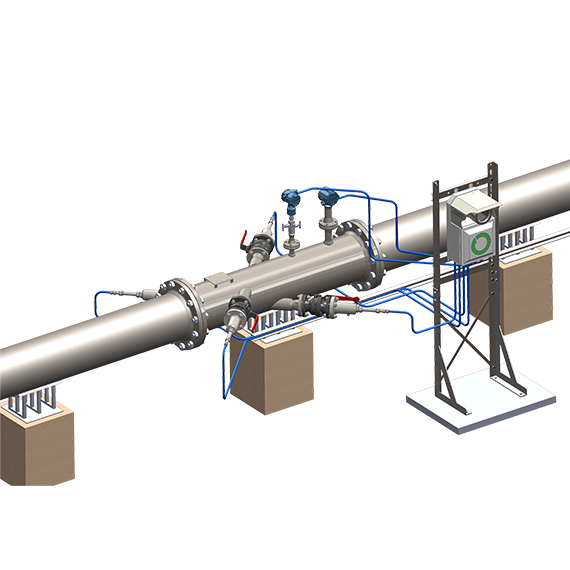

FGM 160 and FGM 160 Dual-Path.

At the heart of the system is the FGM 160 flare gas meter. Designed for the most rugged environments and deployed in harsh conditions around the world, this field computer provides accurate measurement of flare gas across a wide range of operating parameters. The FGM 160 provides flow, mass flow, molecular weight and a range of other data through all commonly used industrial protocols. The FGM 160 Dual-Path provides all the advantaged of our FGM 160 system with an extra measurement path, offering increased accuracy and full redundancy.