Our website uses cookies. By continuing to browse our site you are agreeing to our Cookie Policy.

Surge Relief

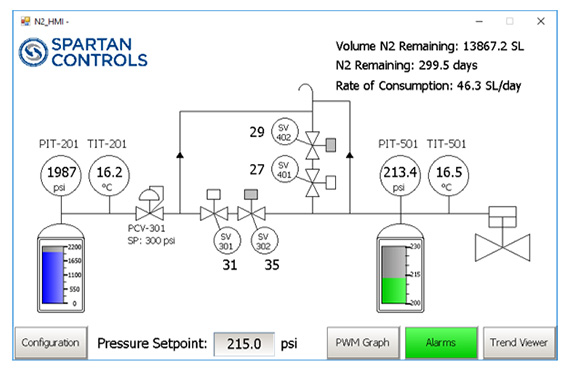

As a stand-alone controller, the SpartanPROTM Surge Relief System enables you to accurately control the nitrogen used to operate a pipeline surge relief valve. The user-friendly HMI, surge event history, nitrogen usage trending, alarming, and remote connectivity make the SpartanPROTM an industry leader in surge relief valve control.

The SpartanPRO™ Surge Relief System is packaged in a weatherproof, insulated and heated enclosure with front and back twin doors. It comes complete with (2) plenum cylinders, a ramp and tie-ins for Customer supplied nitrogen cylinders. The system is fully tested and ready to install upon delivery, we also provide startup and commissioning services if required.

Surge Relief

Specs

Environment

Outdoor -40° to 60°C (40 to 140 °F)

Pressure control accuracy

+/- 3.5 kPag (+/- 0.5 psig)

Nitrogen consumption

Typically, less than 30 SL per day

Digital communication

Modbus RTU, RS485, and Ethernet IP

Power requirements

120 VAC, 60 Hz, 8 amps

Hazardous area classification

Class 1, Zone 2, EX 11A/11B T3 (Class 1, Div 2, Groups C, D T3)

Certifications

cETLus, Nema 4

Cabinet dimensions

64” W x 32” D x 78” H

Features

- High accuracy of nitrogen pressure control

- Continuous health diagnostic reporting

- Extremely low nitrogen consumption

- Robust, fault tolerant design

- Full-colour touchscreen operator interface

- Intuitive, simple front panel user interface allows access to all functions

- Embedded processor for fully autonomous operation

- Advanced remote connectivity