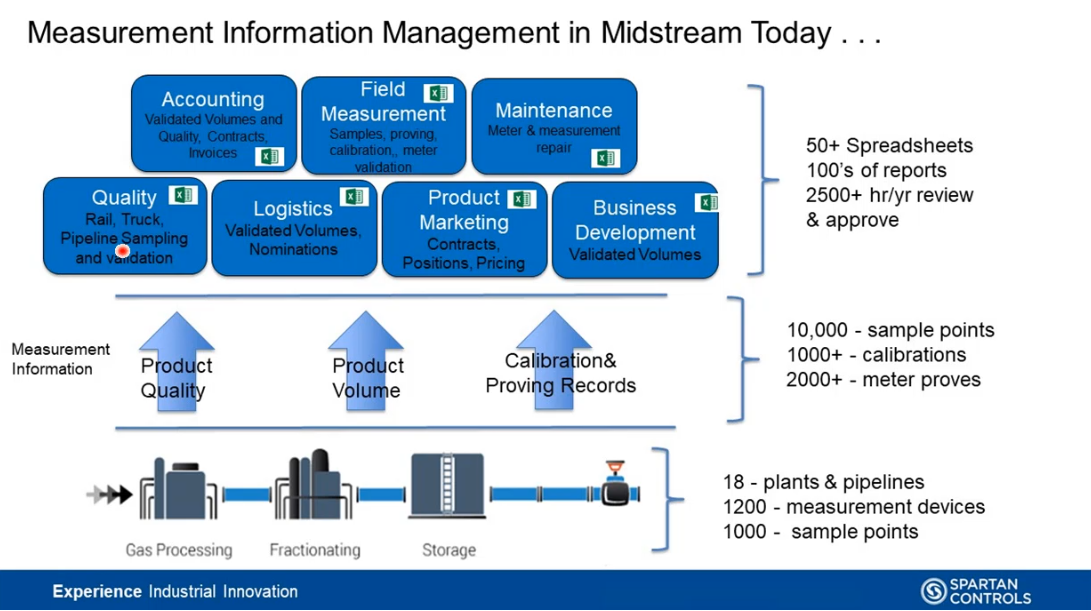

In the blog "Navigating the Data Ecosystem: Challenges in Midstream Operations Measurements" dated March 26, 2024, the author discusses the significant challenges midstream companies face in gathering and interpreting measurement data from various sources. The complexity arises from the scattered nature of data across pipelines, terminals, and different technologies, making it difficult for decision-makers to derive actionable insights.

Key Challenges:

- Data Distribution: Measurement data is widely distributed across different sites and pipeline networks, complicating the compilation of accurate production records.

- Technological Variety: Various technologies, including SCADA, DCS, PLCs, mass flow meters, ultrasonic flow meters, flow computers, and remote telemetry units, generate reports based on these datasets.

- Complex Data Network: The data network includes plant and pipeline automation platforms, track measurement technologies, data historians, lab systems, online analyzers, tank gauging systems, meter calibration systems, proving systems, and truck/rail shipping systems.

- Record Data Inclusion: Accurate evaluation of production records requires the inclusion of product quality data from third-party labs and testing facilities, as well as metadata from SCADA systems.

- Calibration and Proving Systems: Ensuring meters and measuring tools are properly calibrated and adjusted is essential for trustworthy data.

Solution: AspenTech Inmation™ offers a solution to connect these disparate data points into a single secure system. This system can handle various types of data, including flow information, orifice change records, calibration records, lab data, and proving records, and combine them into a single repository. AspenTech Inmation also addresses common OT connectivity challenges, such as gathering multiple data types into a singular database, OT load balancing, and bridging data to IT networks and systems.

To learn more, AspenTech’s partner, Spartan Controls, offers discussions and demos highlighting the value of AspenTech Inmation for the midstream oil and gas production industry.

Blog Written by:

Zack Koulopoulos Marketing Programs Manager, Aspen Technology, Inc.

Full Article