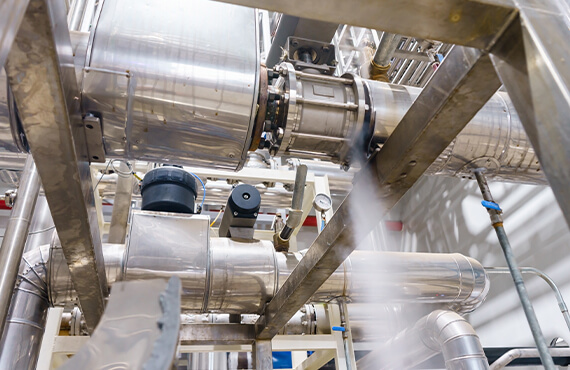

Steam erosion with some liquid cavitation can cause steam blowdown valves to experience body and trim damage.

A significant amount of erosion is estimated to occur through clearance flow, which happens when the valve is closed and high pressure steam flows past the plug seals and seat. Certain materials are able to withstand these process conditions with little effect, while some may have significant damage.