Author: Josh Kolenc

The Critical Role of PRVs in Industrial Safety

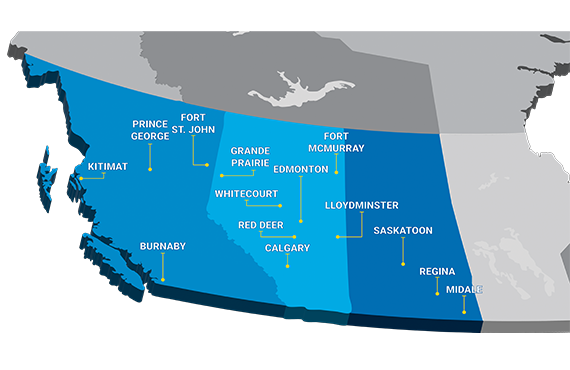

In industries like oil and gas, mining, power generation, and chemical processing, safety and uptime are non-negotiable. Across Alberta, British Columbia, and Saskatchewan, pressure relief valves (PRVs) are essential safety devices—protecting people, equipment, and the environment from dangerous overpressure situations.

PRVs spring into action when pressure builds beyond safe limits, releasing it before it can lead to costly damage or dangerous incidents. As industrial systems grow more advanced and operate under ever-increasing pressures, the performance and reliability of these valves aren’t just important, they’re critical. Keeping a close eye on your PRV health is essential for protecting what matters most.

Meeting Regulatory Requirements in Western Canada

Each province in Western Canada enforces stringent regulations to ensure PRVs are tested, certified, and maintained to the highest standards. Non-compliance can lead to costly penalties, operational shutdowns, and increased safety risks. Here's how compliance is regulated:

- Alberta: Governed by the Pressure Equipment Safety Regulation (PESR) and ABSA’s AB-506.

- British Columbia: Regulated under the BC Safety Standards Act and the Boiler, Pressure Vessel, and Refrigeration Safety Regulation.

- Saskatchewan: Overseen by The Boiler and Pressure Vessel Act, administered by TSASK.

How PRVs Work, and Why They Matter

PRVs are critical safety devices designed to open at a specific set pressure, preventing dangerous overpressure conditions in industrial systems. Often serving as the last line of defense, PRVs play a vital role in protecting people, equipment, and the environment.

Like any mechanical component, PRVs can deteriorate over time due to factors such as:

Like any mechanical component, PRVs can deteriorate over time due to factors such as:

- Corrosion or fouling

- Improper installation

- Mechanical wear

- Exposure to harsh process media

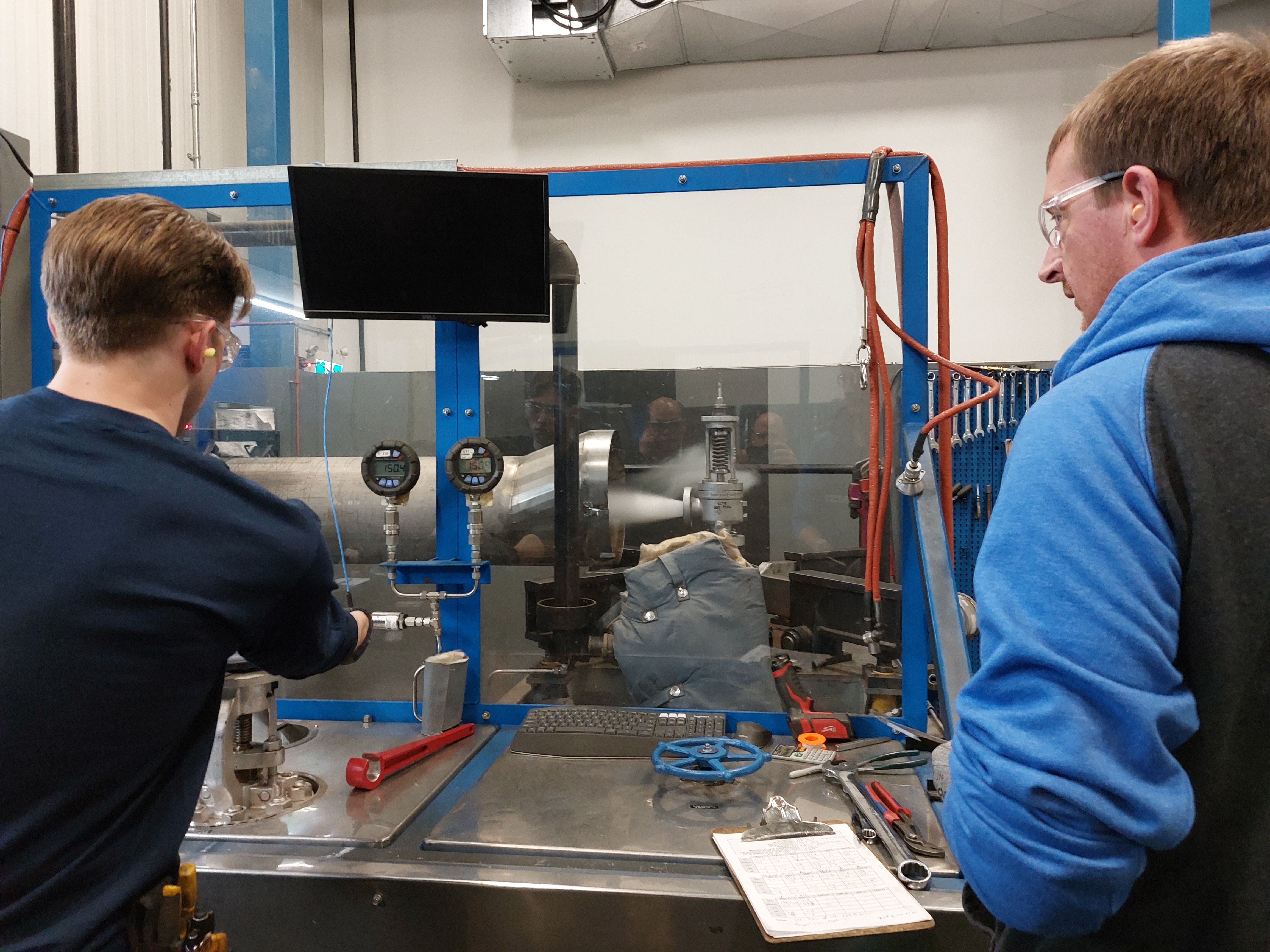

Spartan Controls: Your Partner in PRV Reliability

Spartan Controls offers comprehensive PRV services tailored to the unique demands of Western Canada’s industries. Our expertise spans across steam, gas, and liquid systems, with a full range of certified service capabilities.

Our PRV service offering includes:

- Certified testing and repair for steam, gas, and liquid PRVs

- Clean room testing for oxygen service valves

- Mobile service trucks for on-site testing, repair, and certification

- In-shop services at fully certified facilities

- Exclusive access to Emerson’s trusted Crosby™ and Anderson Greenwood™ PRVs

- Support for all makes and models of PRVs

Specialized Testing Capabilities: Steam and Oxygen Service Valves

Steam Testing for Boiler Safety

In high-pressure steam systems, especially in power generation and heavy industrial applications, boiler safety valves must be tested under live steam conditions to ensure accurate set pressures and In high-pressure steam systems, especially in power reliable operation. Spartan provides live steam testing services that simulate real operating conditions, delivering:

- Precise set pressure verification

- Accurate blowdown measurements

- Full compliance with ASME and provincial codes

Clean Room Testing for Oxygen Service Valves

Valves used in oxygen service require meticulous handling and testing due to the high risk of flammability. Spartan Controls operates a certified clean room specifically designed for:

- Contamination-free testing and repair

- Oxygen cleaning and reassembly

- Compliance with CGA and ASTM standards

Advancing PRV Monitoring with Wireless IIoT Technology

Traditionally, PRVs were difficult to monitor, operators often had no way of knowing if a valve had lifted unless it was visually inspected or triggered an alarm. Today, wireless monitoring and IIoT technologies are transforming PRV management:

- Real-Time Lift Detection: Instantly know when a valve opens

- Duration Monitoring: Track how long the valve remains open

- Remote Access: Monitor valve activity from anywhere, on-site or through Spartan’s managed services

- Data Logging & Analytics: Identify trends, predict failures, and optimize maintenance schedules

These technologies empower maintenance teams to make faster, smarter decisions, improving plant safety while reducing downtime and cost.

Josh Kolenc

Proven Impact: Safety, Uptime, and Cost Control

Implementing a proactive PRV monitoring strategy can lead to:

- Fewer unplanned shutdowns

- Improved regulatory compliance

- Enhanced worker safety

- Lower maintenance costs

- Data-driven decision-making

A Safer, Smarter Future with Spartan Controls

Pressure relief valves are more than just mechanical components, they are vital safety systems. In Alberta, BC, and Saskatchewan, ensuring their reliability is not just a regulatory requirement, it’s an operational imperative.

Spartan Controls provides certified PRV services, mobile field support, clean room capabilities, exclusive access to industry-leading valve technologies, and advanced wireless monitoring. Whether you operate a SAGD facility in northern Alberta, a pulp and paper mill in BC, or a power station in Saskatchewan, Spartan is your trusted partner in PRV safety and performance.

Spartan Controls provides certified PRV services, mobile field support, clean room capabilities, exclusive access to industry-leading valve technologies, and advanced wireless monitoring. Whether you operate a SAGD facility in northern Alberta, a pulp and paper mill in BC, or a power station in Saskatchewan, Spartan is your trusted partner in PRV safety and performance.