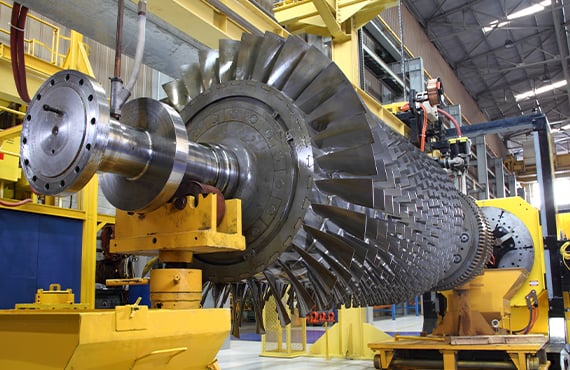

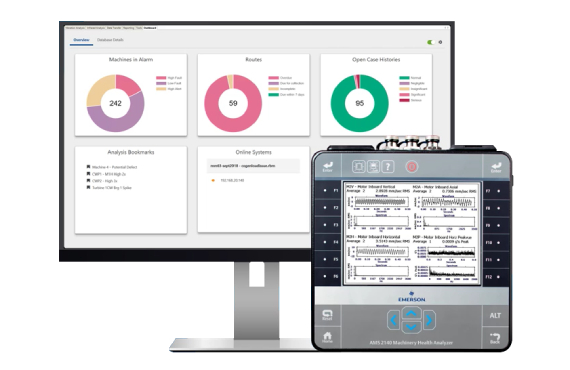

Technology to Predict & Prevent Equipment Failure to Increase Profit

Today, industry leaders realize that a proactive, management led reliability strategy is the secret to improved shareholder value. It’s the secret weapon against declining operational performance, improved production availability and lower operating costs. It also keeps you off the evening news.

Spartan Controls has the most comprehensive portfolio of services and technologies to support your vision of Top Quartile Reliability.