Our website uses cookies. By continuing to browse our site you are agreeing to our Cookie Policy.

HIPPS

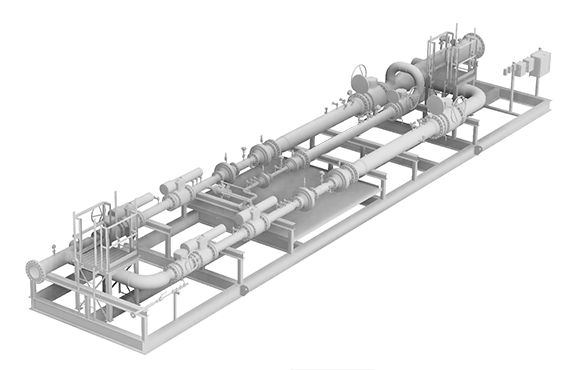

High Integrity Pressure Protection Systems are designed to enhance or replace over pressure protection traditionally addressed with mechanical relief and flare systems.

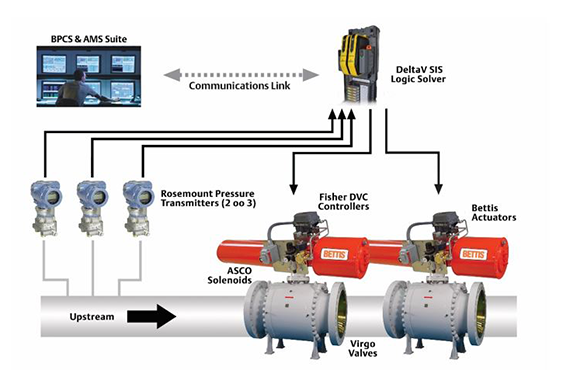

Unlike a mechanical relief or flare system, a HIPPS system is designed to close the valves and isolate the process at its source when an over-pressurization event is detected. This eliminates the loss of product and fugitive emissions associated with relief systems.

HIPPS has a relatively low-cost compared to the total installed and commissioned cost of a flare system and the associated header piping.

Spartan and Emerson are able to provide full Turnkey Systems for HIPPS including:

- SIL Certified Automation Components

- HIPPS Cabinet Design, Fabrication and Configuration

- HIPPS Configuration

- Valve Assembly & Testing

- SIL Verification Calculations

- Partial Stroke Test Calibration and Training

- Complete System FAT

- Project Management

-

Engineering

HIPPS Applications

Inlets to industrial applications for over pressure include Refineries, Petrochemical Facilities, NGL Fractionation Facilities, and Power Plants:

- Compression & Pumping Systems

- Natural gas gathering systems

- Interstate pipeline systems

- Dew point processing plants

- Underground storage facilities and terminals as well as vessel, train and truck loading facilities

Features

- HIPPS is designed to close the valve and isolate the process at its source when an over pressurization event is detected

- Controlled by DeltaV SIS

Get in touch with an expert, find your nearest office location, or send us a note about your next project!!

Talk to one of our experts in this field

+1 (877) 278-6404

+