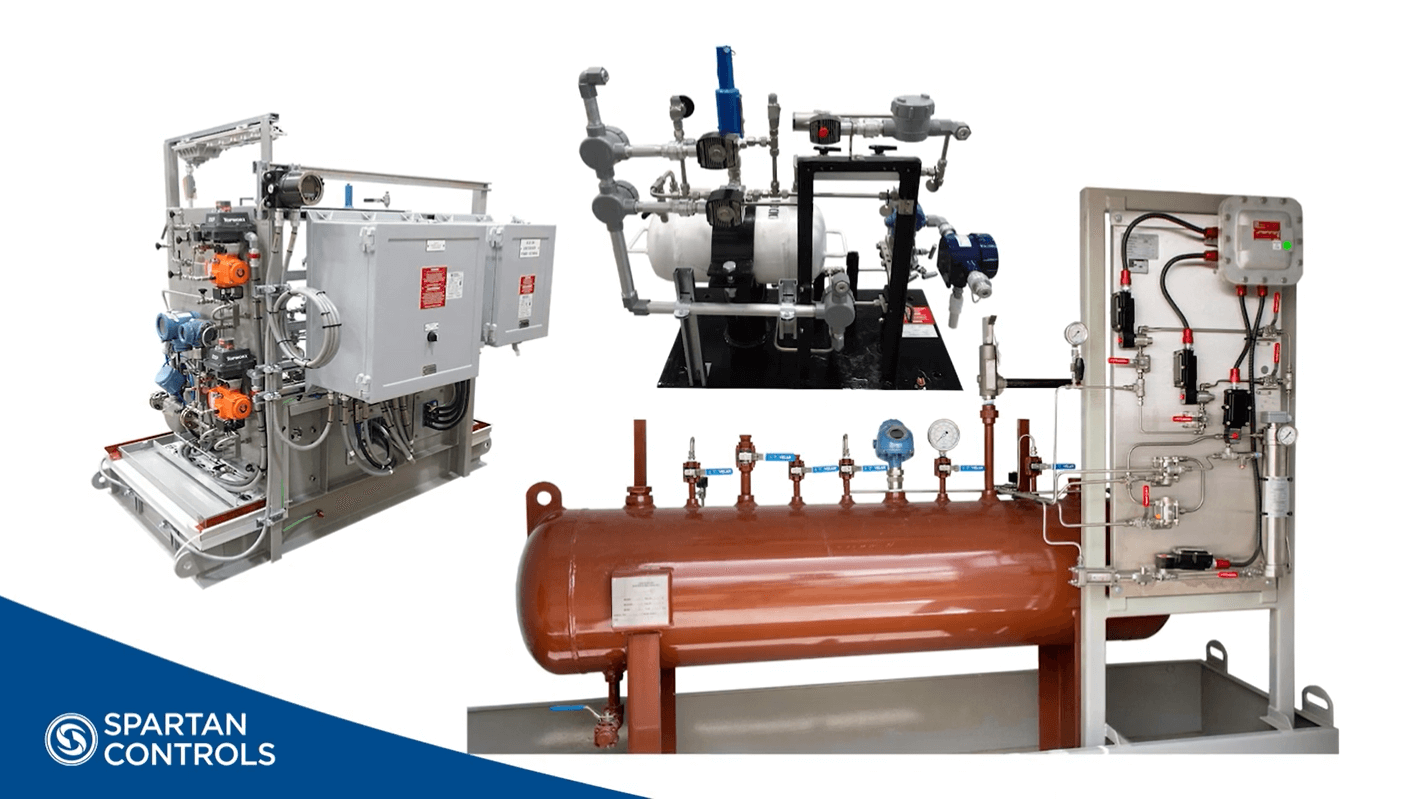

Industrial Odorization Technologies & Applications

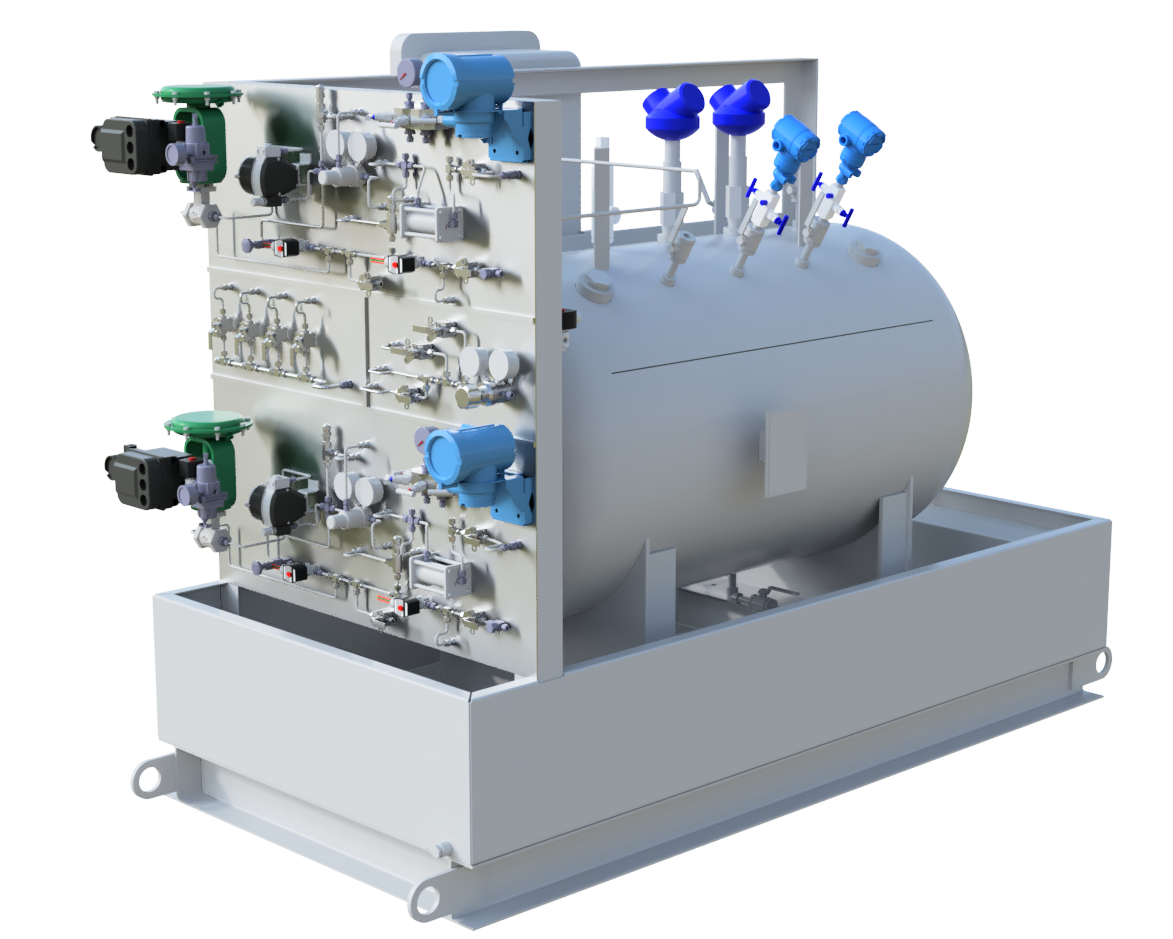

Pressurized Tank Odorizer for low to medium odorant flow rates

Odorizing gas with pump-based systems is challenging. The turndown ratio of the overall system is limited by the pumps themselves, and the pumps require regular maintenance to perform reliably.

The Spartan Controls Pressurized Tank Odorizer simplifies this application with a unit that offers automated controls for varying flow rates, simplified operation, low power consumption, accurate dosing and low maintenance.

The Spartan Controls Pressurized Tank Odorizer simplifies this application with a unit that offers automated controls for varying flow rates, simplified operation, low power consumption, accurate dosing and low maintenance.