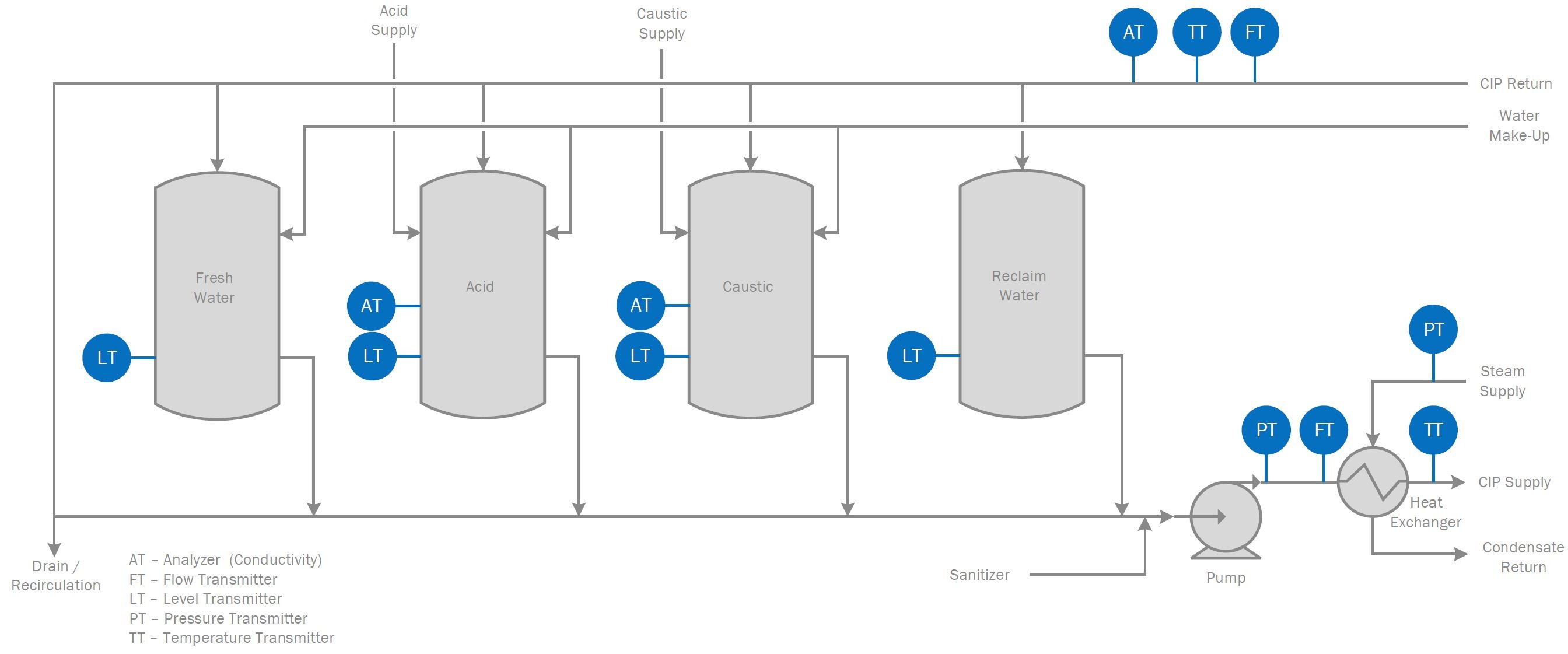

Ensuring the efficacy of Clean-in-Place/Mobile Clean-in-Place (CIP) processes for a Food & Beverage processing facility requires precise measurement and control.

Without the right systems in place, managing the sequencing of lines and vessels for cleaning while optimizing production can be a scheduling challenge. Spartan Controls’ process equipment and control systems provide a lower-cost, regulatory-compliant solution that increases efficiency, improves safety by reducing cross-contamination, and offers greater assurance of product quality.