Author: Andre Dicaire

Introduction

With the release of DeltaV™ Version 14, Emerson has completed a modernization of the DeltaV Integrated Control and Safety System (ICSS). One of the primary features of this release is the PK family of controllers. In this discussion, we will look at why this new controller platform changes the game for DeltaV systems and for the industry collectively.

The PK controller is the most powerful processor built for the DeltaV system.

Andre Dicaire, Author

Some History

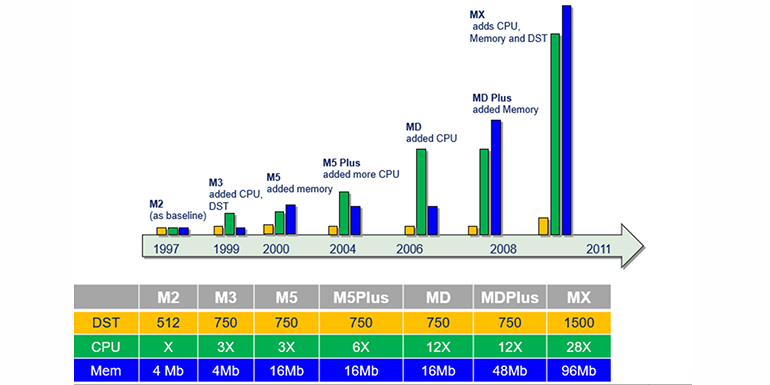

Introduced in 1996, the DeltaV system was the first DCS based on Consumer Off The Shelf (COTS) products, such as a PC running Windows Operating system, 3COMM Network Hubs and Ethernet hardware. It also introduced the M-Series controllers with the M2 processor. The system was small at first, but quickly grew in node count and IO capacity. By 2010, the DeltaV system had grown from the initial 512 Device Signal Tags (DST) to 30,000, and from 4 nodes to 120 nodes per zone, and 15 zones for up to 450,000 connected devices.

During this time, Emerson released a series of controllers in conjunction with system size increases as end users demanded more capacity within a single controller. Each new platform delivered increased capacity in one of three areas: user memory, control capacity and DST IO size.

During this time, Emerson released a series of controllers in conjunction with system size increases as end users demanded more capacity within a single controller. Each new platform delivered increased capacity in one of three areas: user memory, control capacity and DST IO size.

Figure 1: M Series Controller Evolution

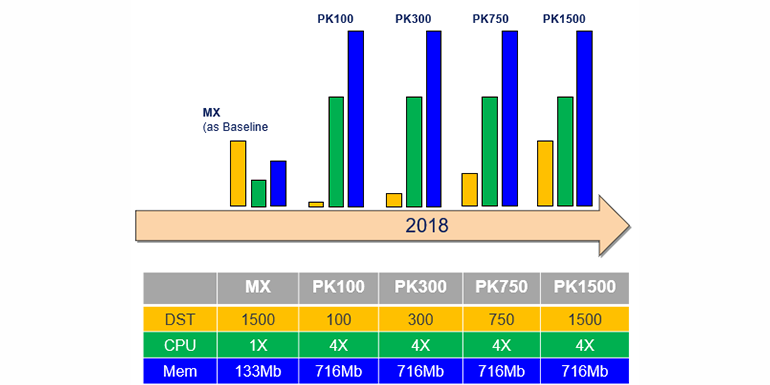

In Version 11, the DeltaV system introduced the S Series controllers to support the new Electronic Marshalling with CHARMs. The MQ and SQ controllers were released in 2012 to replace the MDPlus and SDPlus; the MX/MQ and SX/SQ remained the flagship controllers of the DeltaV system, until 2018, when Version 14 introduced the PK family of controllers.

The PK controller is the most powerful processor built for the DeltaV system, delivering nearly four times the control capacity, as compared to the SX controllers and six times the user memory.

The PK controller is the most powerful processor built for the DeltaV system, delivering nearly four times the control capacity, as compared to the SX controllers and six times the user memory.

Figure 2: PK Controller Capacities

PK Hardware

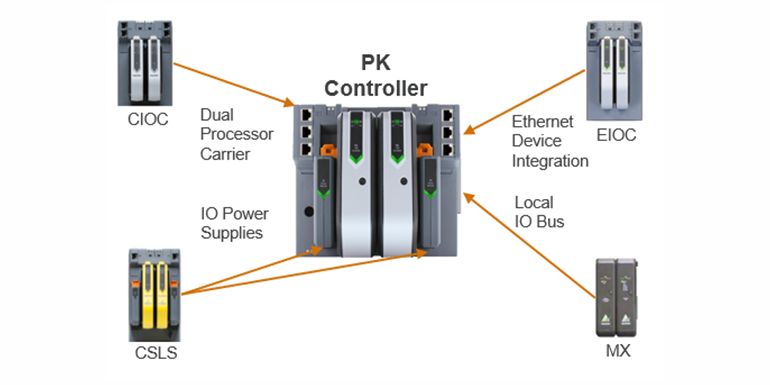

When compared to the previous M-series and S-Series controllers, the PK appears to be a radical change in hardware design. However, the PK controller does not introduce any new design features, but rather brings together several design features of previous DeltaV products.

The main design features of the PK controller come from the following innovations of the DeltaV system:

The main design features of the PK controller come from the following innovations of the DeltaV system:

- V2: The PK controller supports the Local M-Series IO Cards of the original DeltaV M-series controllers.

- V11: The CHARM IO Card (CIOC) which introduced a dual slot carrier with redundant Ethernet communication modules.

- V12: The DeltaV SIS CHARM Safety Logic Solver introduced the IO Power supplies to the carrier, powering to the 96 Safety CHARMS connected to the CSLS.

- V12: The SZ controller introduced network segregation with an Ethernet Communication module that connects to both the DeltaV Network and SIS local Safety network.

- V13: The Ethernet IO Card (EIOC) provides integration of Subsystems drivers for ModbusTCP, Ethernet/IP and the IEC61850 protocol for electrical switchgear integration.

Figure 3: PK Design Features / Influenced Technologies

Controller Operating System

The PK controller runs the same Operating system as the SX and SQ controllers. This OS was introduced to the controllers in v12, along with the SZ controller. It was originally deployed on the CIOC’s in v11 before making its debut on DeltaV controllers. In v13, the EIOC was introduced with this OS, along with its Ethernet Drivers integrated with the Control Module architecture.

In addition to the common physical design features that the PK shares with previous DeltaV products, it also shares the same software and firmware features that have been proven in use for multiple versions of the system. With the release of v14, all controllers now run the same operating system—the M-series controllers now sharing the same firmware as their S-series counter parts.

In addition to the common physical design features that the PK shares with previous DeltaV products, it also shares the same software and firmware features that have been proven in use for multiple versions of the system. With the release of v14, all controllers now run the same operating system—the M-series controllers now sharing the same firmware as their S-series counter parts.

These two server protocols can be enabled at the same time along with the Ethernet IO Device Driver, which makes the PK controller the most connected controller in the DeltaV System.

Andre Dicaire

Native Ethernet Drivers

The PK controller introduces native support for Ethernet drivers without the need for additional hardware or software. In prior controllers, a Virtual IO Module (VIM) was required to connect Ethernet field devices via MODBUS TCP, Ethernet/IP or Profinet protocols. The VIMNet Explorer software is used to configure the VIM, allowing the Ethernet device data to be mapped to DeltaV Serial card datasets, acting as a data concentrator between the DeltaV controller and the Ethernet network. The native drivers in the PK eliminate this external configuration task and land the device data directly into PK controller IO signals. This is ideal for integrating Variable Frequency Drives (VFD’s), protection relays and MCCs to the controller, eliminating the need for additional hardware such as the VIM.

The native Ethernet drivers provide increased throughput over the VIM by avoiding the local IO bus. Devices land data directly in the controller at full 100 MB Ethernet bandwidth with no added latency. Other benefits include native configuration within the DeltaV configuration tools. Both the Ethernet Driver license and physical connection points are included with the PK controller. In all, this simplifies device integration, eliminates additional costs of the VIM, reduces footprint, and improves overall performance and availability.

The native Ethernet drivers provide increased throughput over the VIM by avoiding the local IO bus. Devices land data directly in the controller at full 100 MB Ethernet bandwidth with no added latency. Other benefits include native configuration within the DeltaV configuration tools. Both the Ethernet Driver license and physical connection points are included with the PK controller. In all, this simplifies device integration, eliminates additional costs of the VIM, reduces footprint, and improves overall performance and availability.

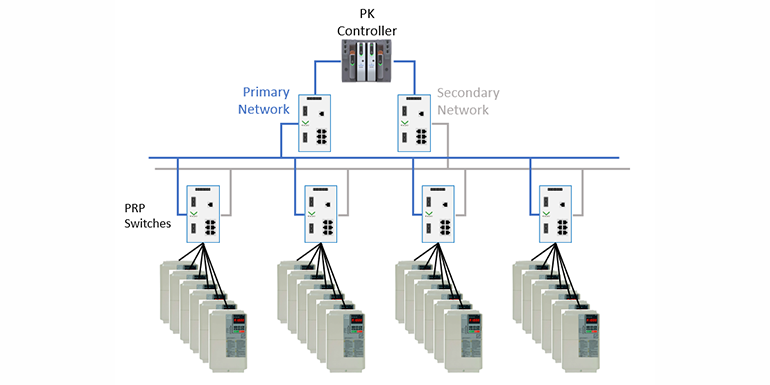

PRP Network Architecture

The PK controller also follows the introduction of the Parallel Redundant Protocol (PRP) to the EIOC in v14, which allows for two different network topologies depending on the requirements of the project. The Ethernet device network can be set up as two different subnets, acting either as A and B networks for simplex devices, or to connect devices with separate redundant ports, or to deploy a PRP network for high availability systems.

The PK controller also supports two data server protocols: OPC UA and MODBUS TCP. These servers can be used with a local third-party HMI, or a history data collector when deployed in a standalone scenario (more on that topic in a subsequent article). These two server protocols can be enabled at the same time along with the Ethernet IO Device Driver, which makes the PK controller the most connected controller in the DeltaV System.

The PK controller also supports two data server protocols: OPC UA and MODBUS TCP. These servers can be used with a local third-party HMI, or a history data collector when deployed in a standalone scenario (more on that topic in a subsequent article). These two server protocols can be enabled at the same time along with the Ethernet IO Device Driver, which makes the PK controller the most connected controller in the DeltaV System.

Figure 4: PRP Network with Double Attached Nodes via Switches

Summary

The PK controller family provides a step change in performance for the DeltaV

system. Coupled with the new DeltaV™ Live HMI and the hardware innovations of the last few releases, the DeltaV system has completely re-invented itself. There is still much to discuss about the PK controller—more to come soon.

system. Coupled with the new DeltaV™ Live HMI and the hardware innovations of the last few releases, the DeltaV system has completely re-invented itself. There is still much to discuss about the PK controller—more to come soon.

Want to Learn More?

Connect with One of our Spartans

Creating a Sustainable Modern World with Innovative Automation. Learn how we help companies just like yours.

Learn More